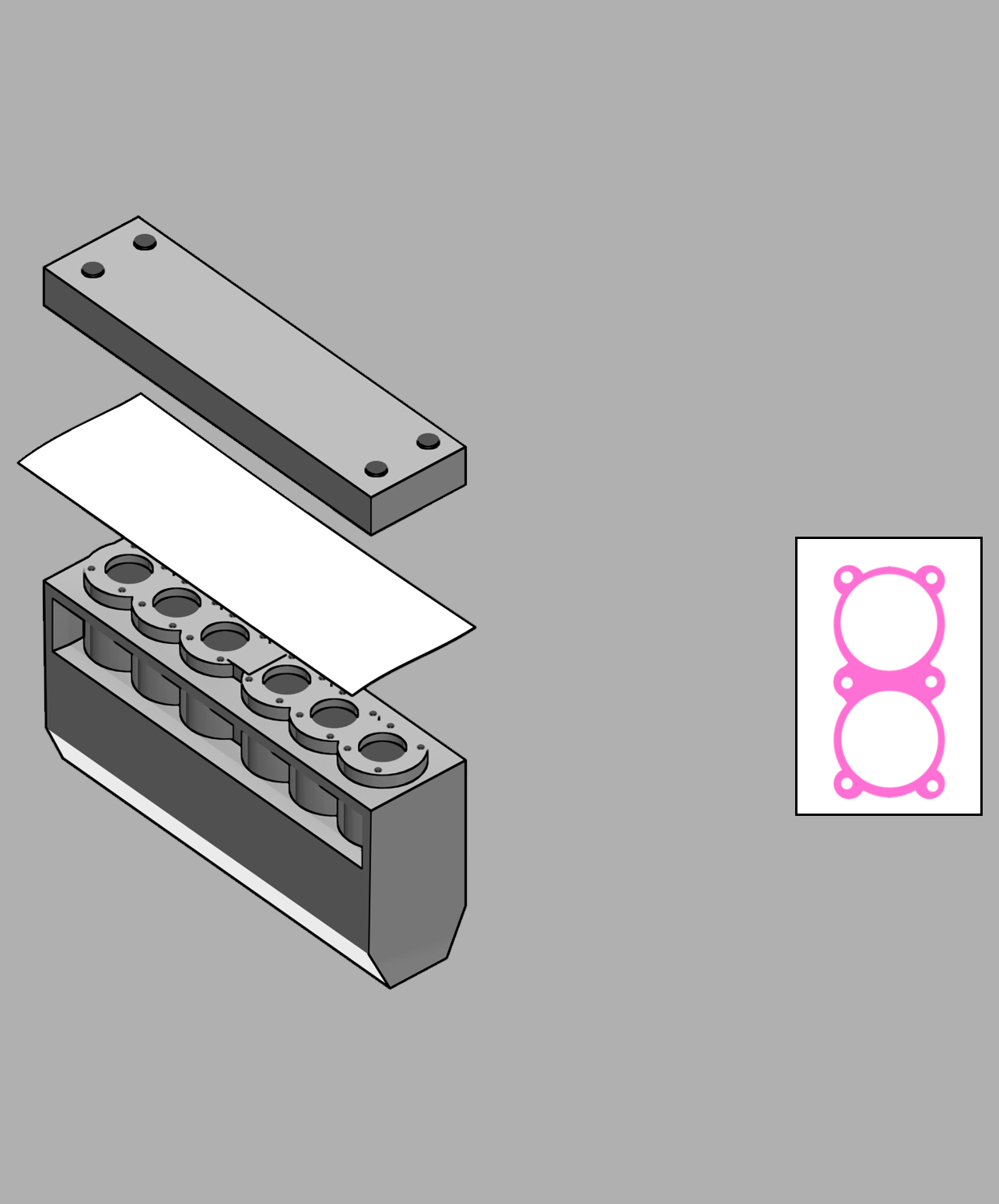

The engine must be designed to ensure that the engine combustion chamber openings are properly sealed. For this purpose, the material of the engine block, the fastener, the lubrication of the fastener, the magnitude and order of the fastening moment, and the design of the gasket must be carefully chosen and determined. The PF pressure film produced by Kumlong International Limited can measure the dynamic pressure distribution state and provide designers with accurate and real-time pressure size and distribution data to make the best choice and decision.

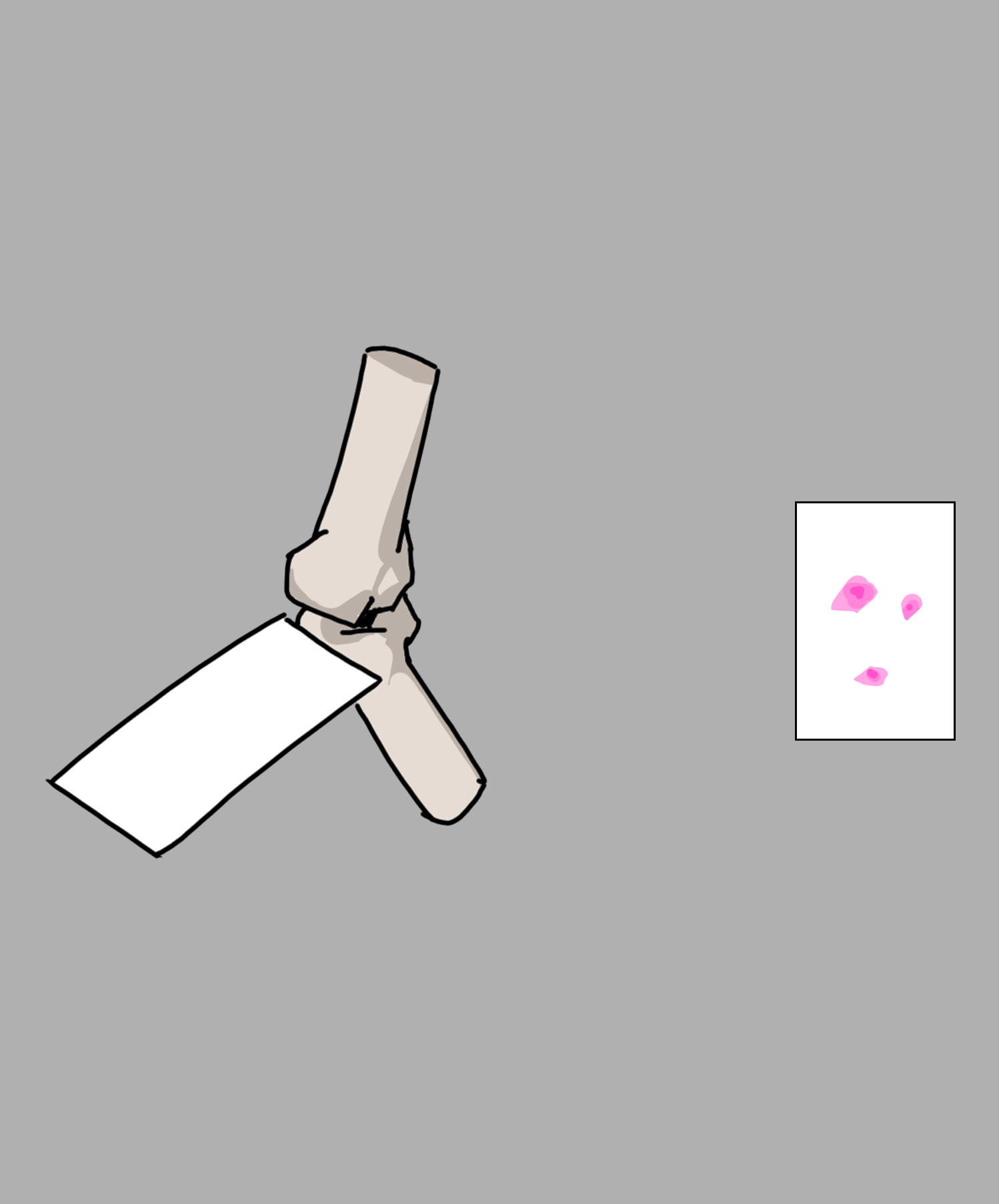

PF pressure films can provide medical researchers with a tool to better understand how the bone and joint interface of the human body performs its function and bears capacity.PF can quickly measure the pressure distribution of knee, ankle, wrist, hip, elbow and shoulder and other bone joints and contact surfaces, providing reference data for mechanical and finite stress analysis, and providing an efficient and economical test tool for the mass manufacturers and medical evaluation units.

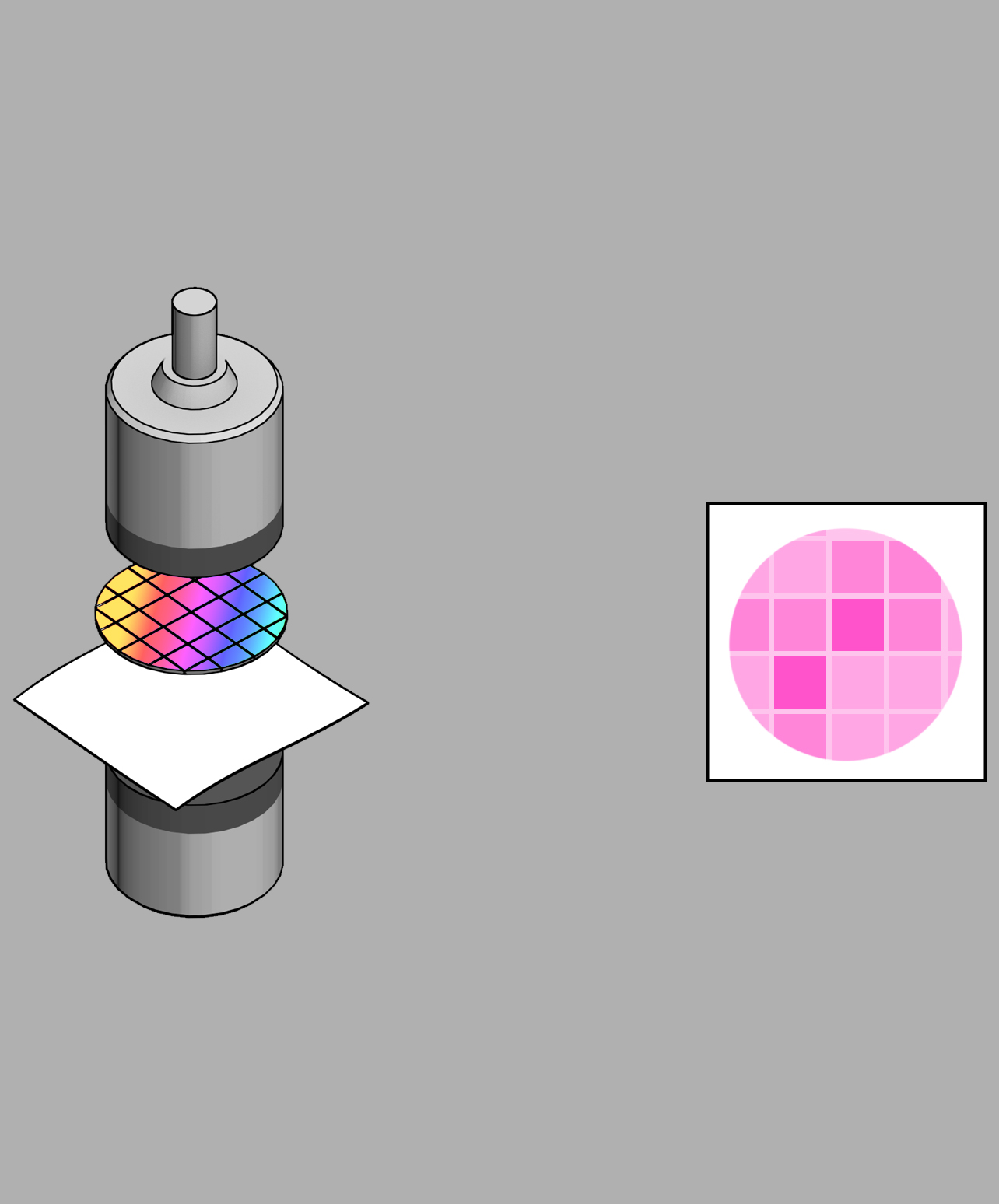

The Rolls play a very important role in papermaking, printing, leather making, battery manufacturing and other industries. Physical parameters such as pressure, clearance and balance of the upper and lower rollers will directly affect the quality of the final product. PF pressure film can simply and intuitively display the pressure situation between the upper and lower rollers, such as the depth of color and the number of contact area, which can provide a reference for roller manufacturers.

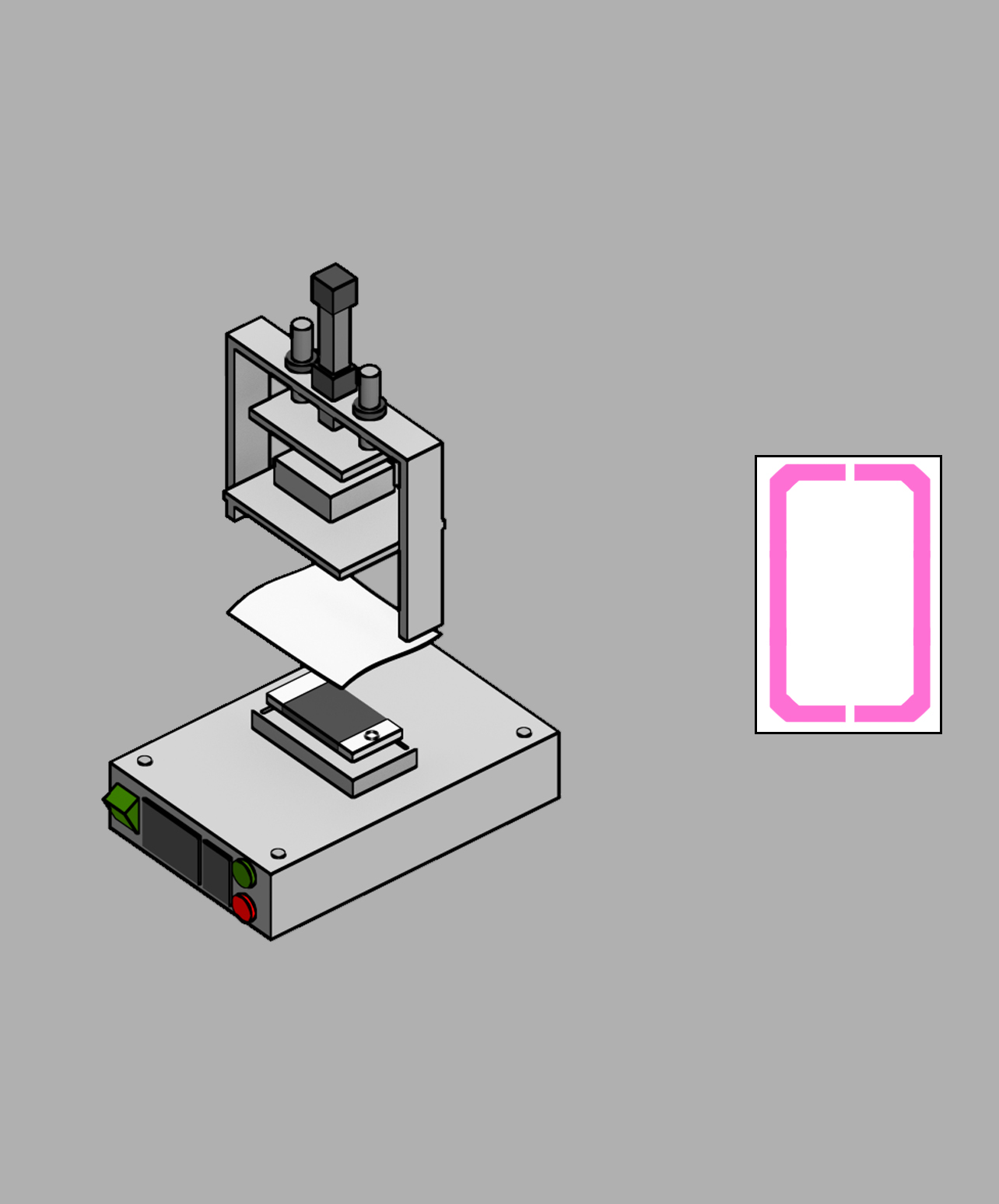

During the wafer manufacturing, the silicon wafers need to be pressed by a high-pressure machine. Whether the pressure between the two molds on the machine can be uniformly conducted or whether the molds are smooth plays an important role in wafer manufacture process. The 0.1mm PF presure film can visually display the pressure distribution between the silicon wafer pressing molds, which is an important tool for silicon wafer R&D and machine manufacturers.

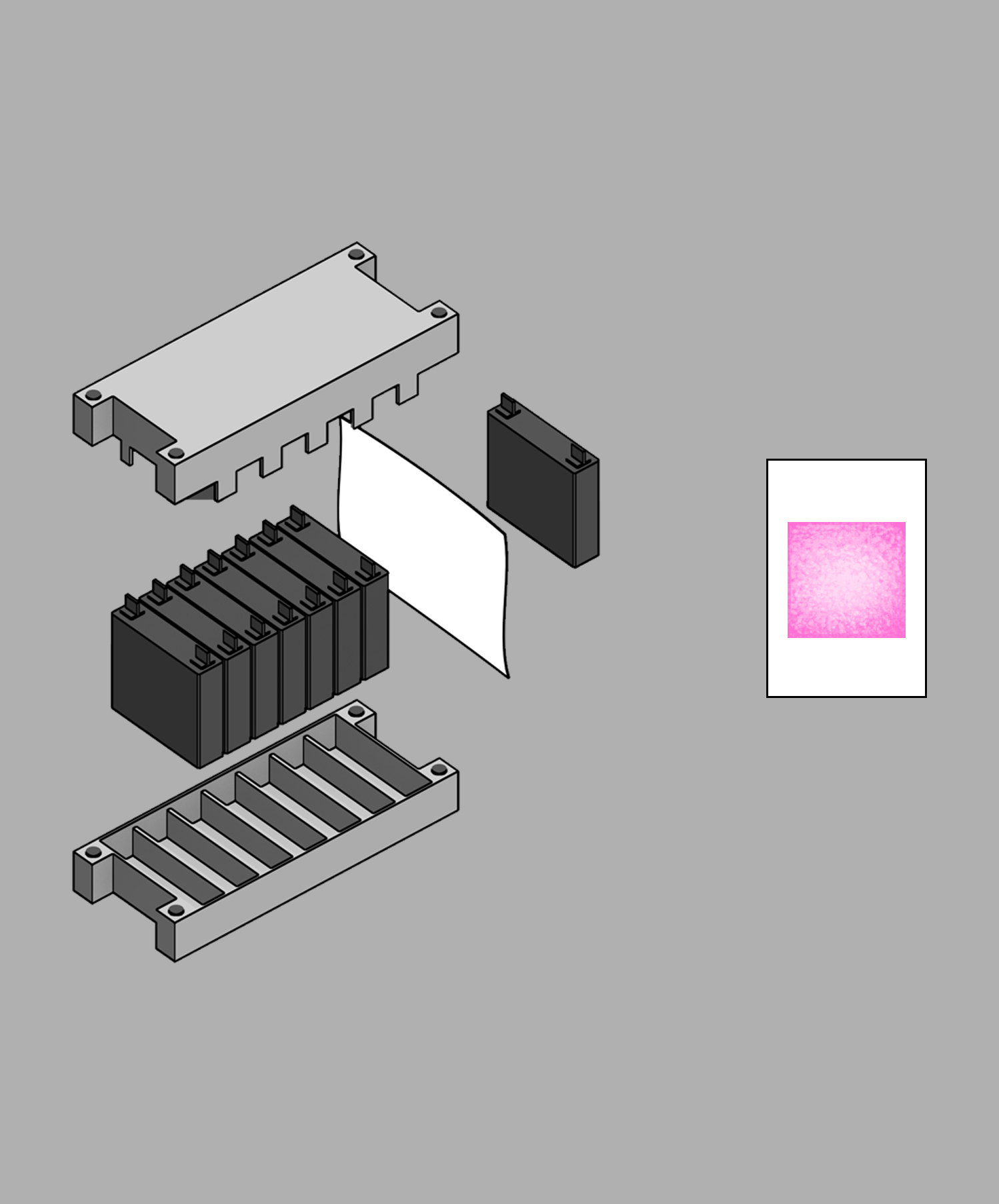

During the charging and discharging process of lithium battery, internal expansion will occur in lithium battery. In order to better understand the pressure of expansion on lithium battery pack, PF pressure color film must be used to provide reference for its pressure. PF pressure film can clearly show the pressure distribution between lithium battery packs, providing R&D engineers with better solutions to defects in the battery design process and production engineering, such as coating uniformity and pressure uniformity of steel roller.

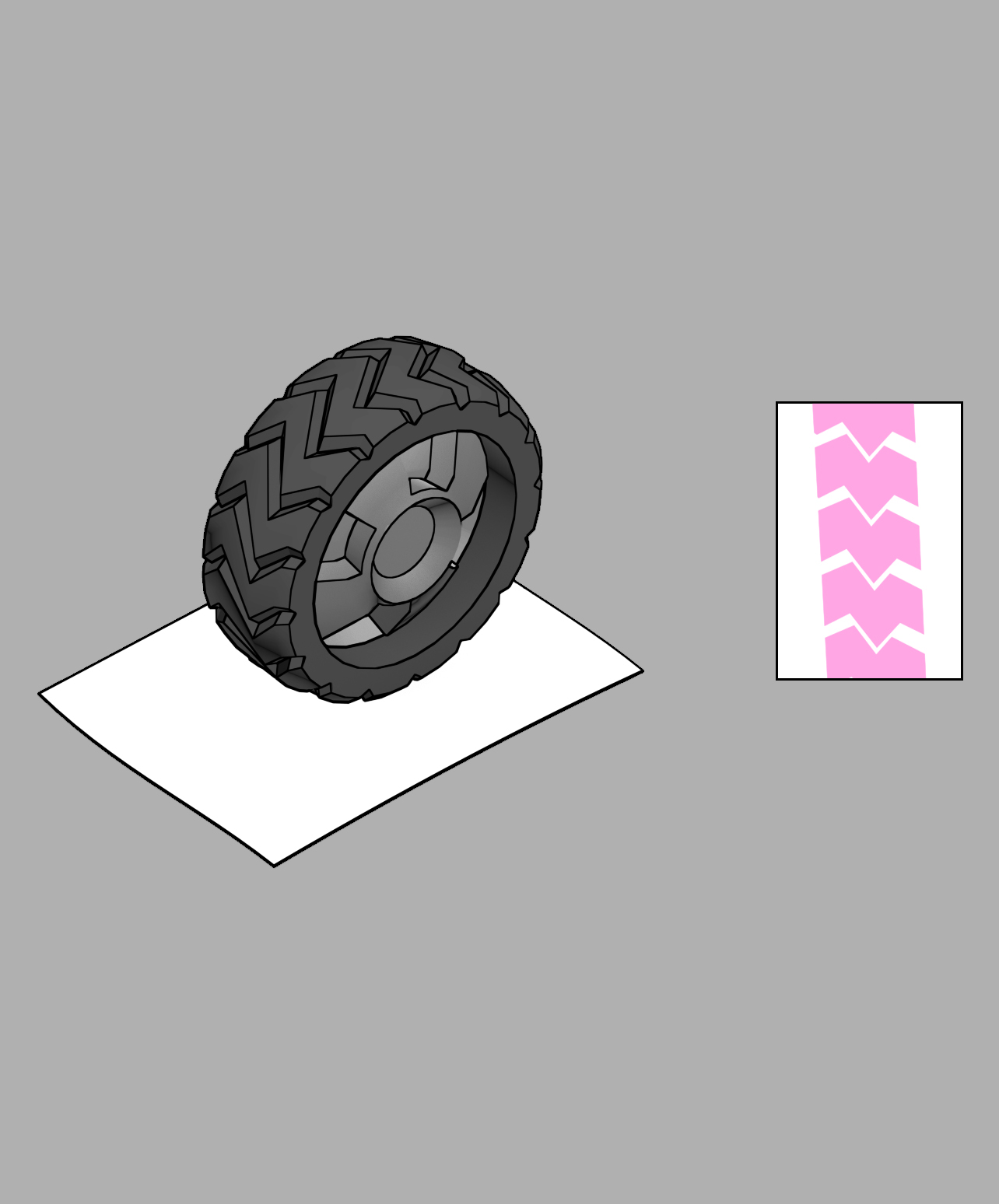

PF pressure film can show the distribution of tire contact pressure. The intuitive images can be used for qualitative and quantitative analysis, and can quickly display the contact area, edge area, tread length and width, and pressure distribution of section of the tire. Then it is easy to compare the characteristics of a variety of tires with each other, or to compare the characteristics of a tire under different loading and inflation conditions. These information helps designers and manufacturers analyze the composition and tread design of different tires, perform quality control measurements, making reference standards, and assess the impact of vehicle suspension.

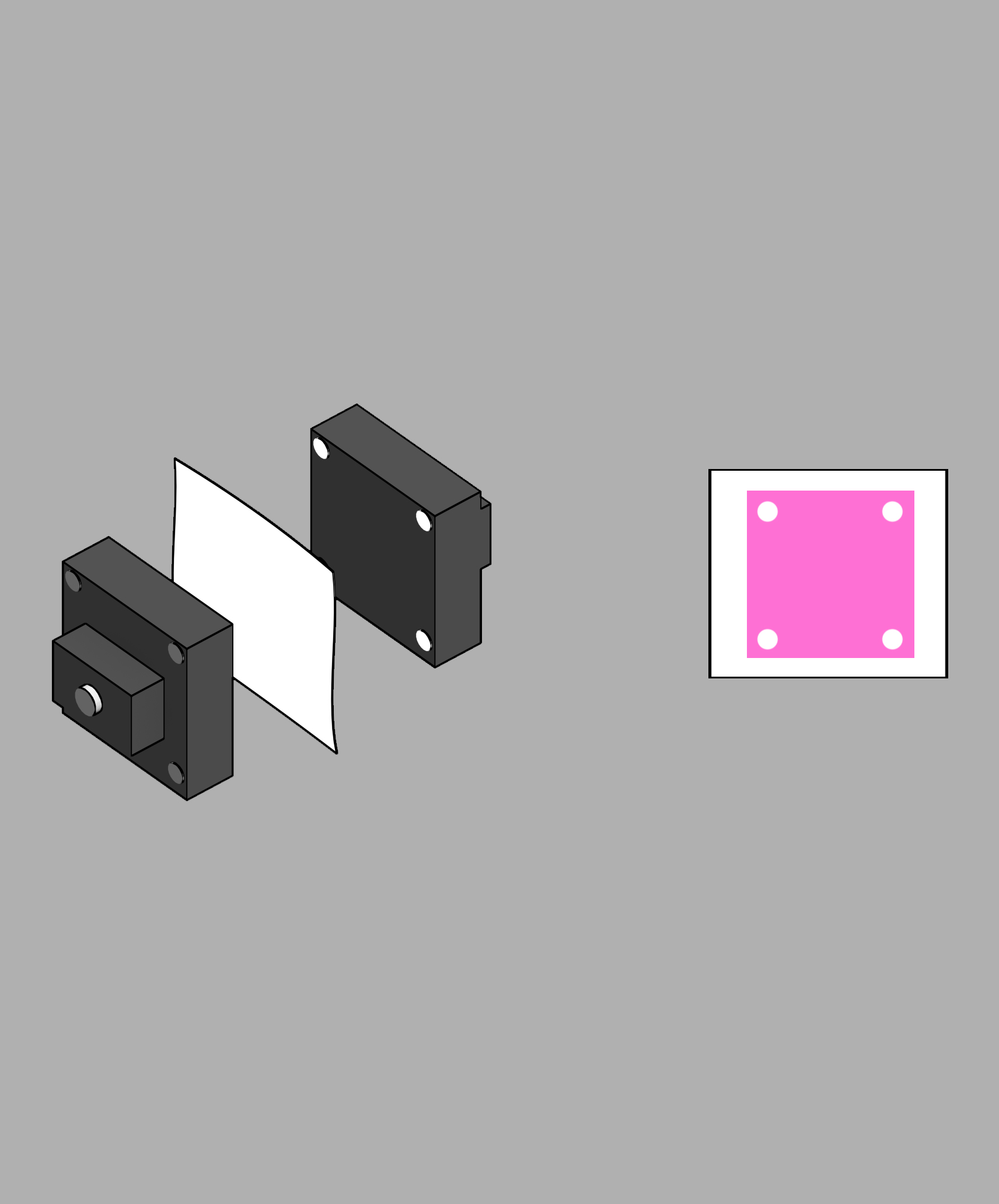

Unknown clamping forces in the installation of computer chips and heat sinks will cause great product defects and quality problems, reduce output and product qualification rate, and increase costs. PF pressure film is a key diagnostic and equipment installation tool for clamping and fixing. The ultra-thin color-indicating film (0.1mm) can be placed between any two contact surfaces, such as a radiator and a heat source, to show the pressure distribution between the clamping fixture and the bearing surface.

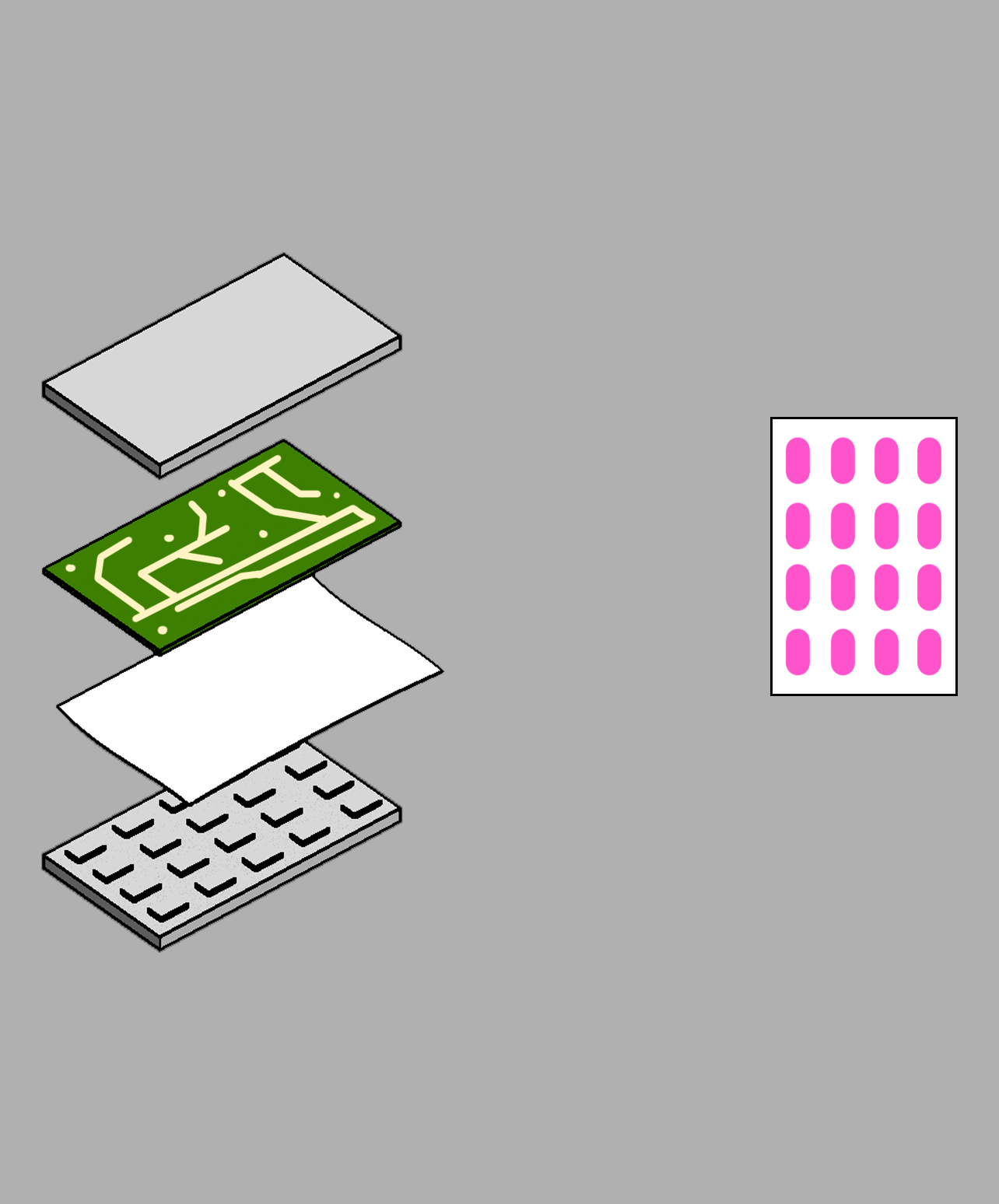

In the manufacturing process of PCB printed soft board, it needs to be pressed through the press machine. PF pressure film can quickly provide efficient evaluation for on-line detection. PF2 pressure film can indicate the color below 100 ° C, which also solves the problem of PCB under high temperature and high pressure.

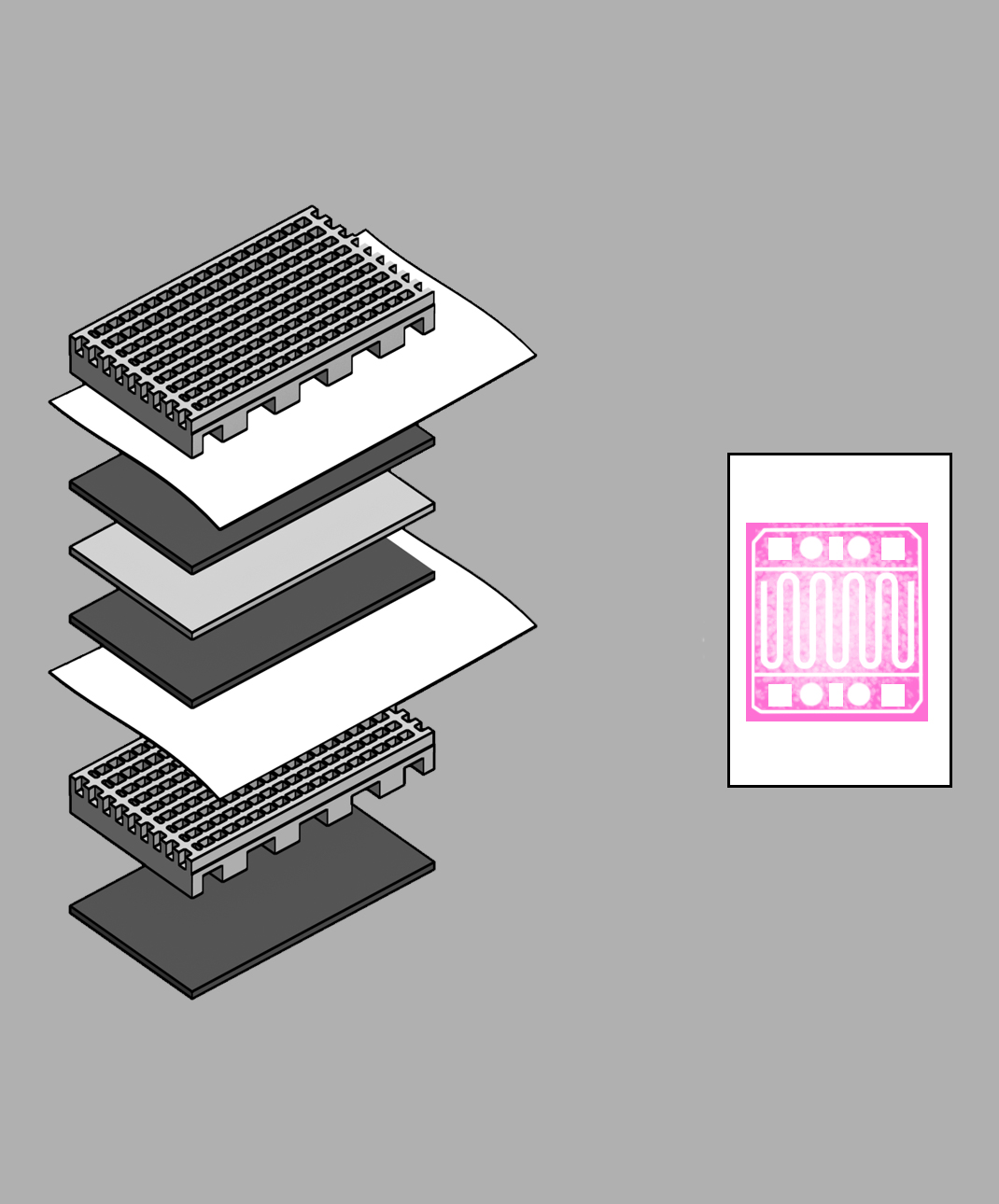

PF pressure film is one important tool for fuel cell development and design. In a fuel cell, many plates are stacked in a small space to separate the flow of hydrogen and oxygen. Maintaining or improving the uniformity of large area contact pressures between these plates is an important factor in fuel cell design and function. Eliminating some of the possible vulnerabilities is also a key to effective fuel cell applications. PF pressure film provides reliable data for analysis of the above problems in fuel cell design and manufacturing.

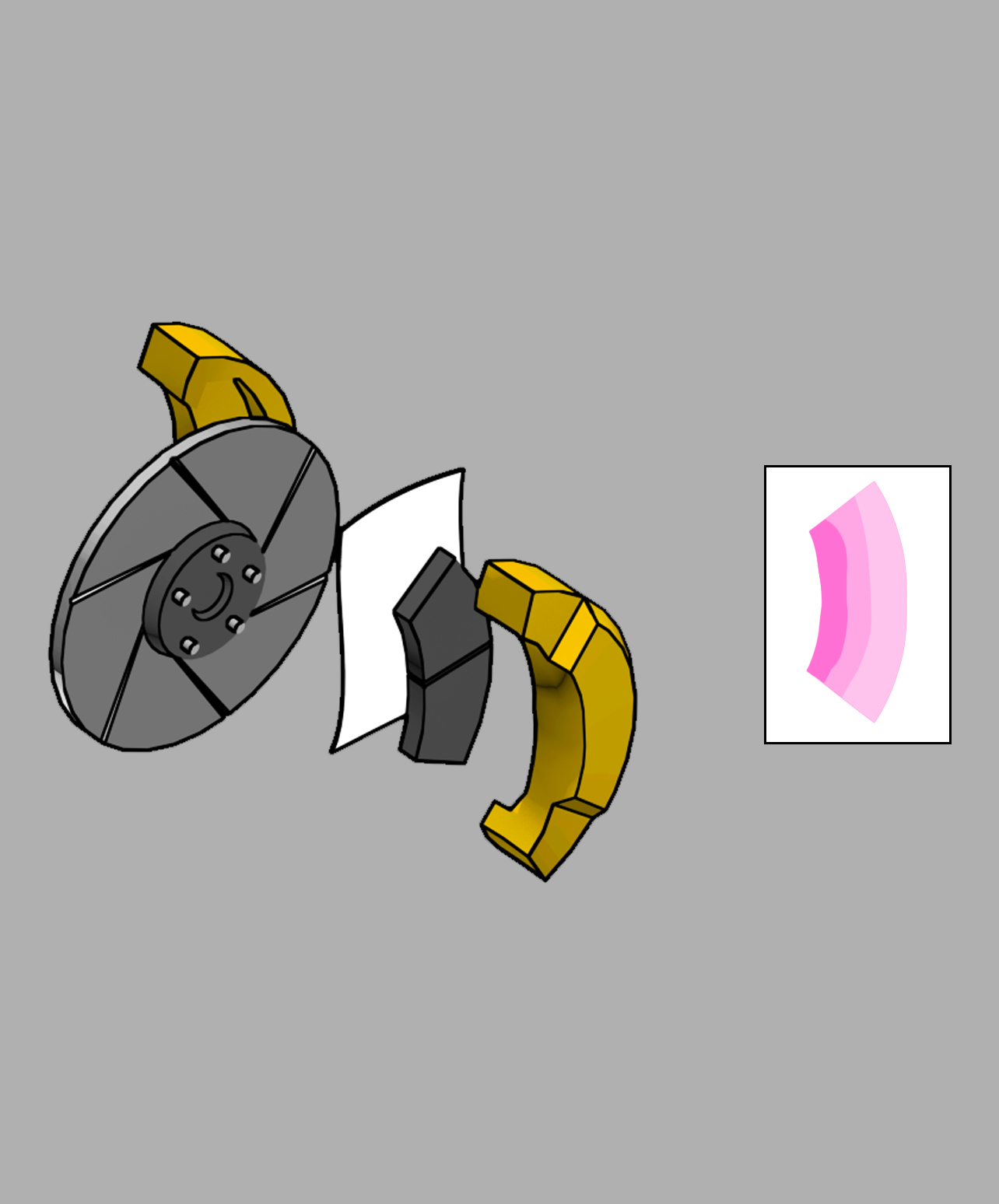

PF can instantly understand the contact force between dynamic brake pads and rotor or brake skin and brake drum. The pressure indicating image obtained from the color developing surface can clearly show the parts with uneven pressure on the contact surface and predict the wear and pressure of the gasket. This information can help to solve the problems faced by brake pad designers through design improvements, such as reducing brake noise and vibration.

In the process of mobile phone manufacturing, R&D engineers will encounter a lot of the question of whether internal structure glue evenly in mobile phone, such as the dispensing process between screen and frame is pressing by pressing machine, PF pressure film can be directly and clearly shows the pressure situation between pressure machine and mobile phone screen, or, between phone screen and phone frame.

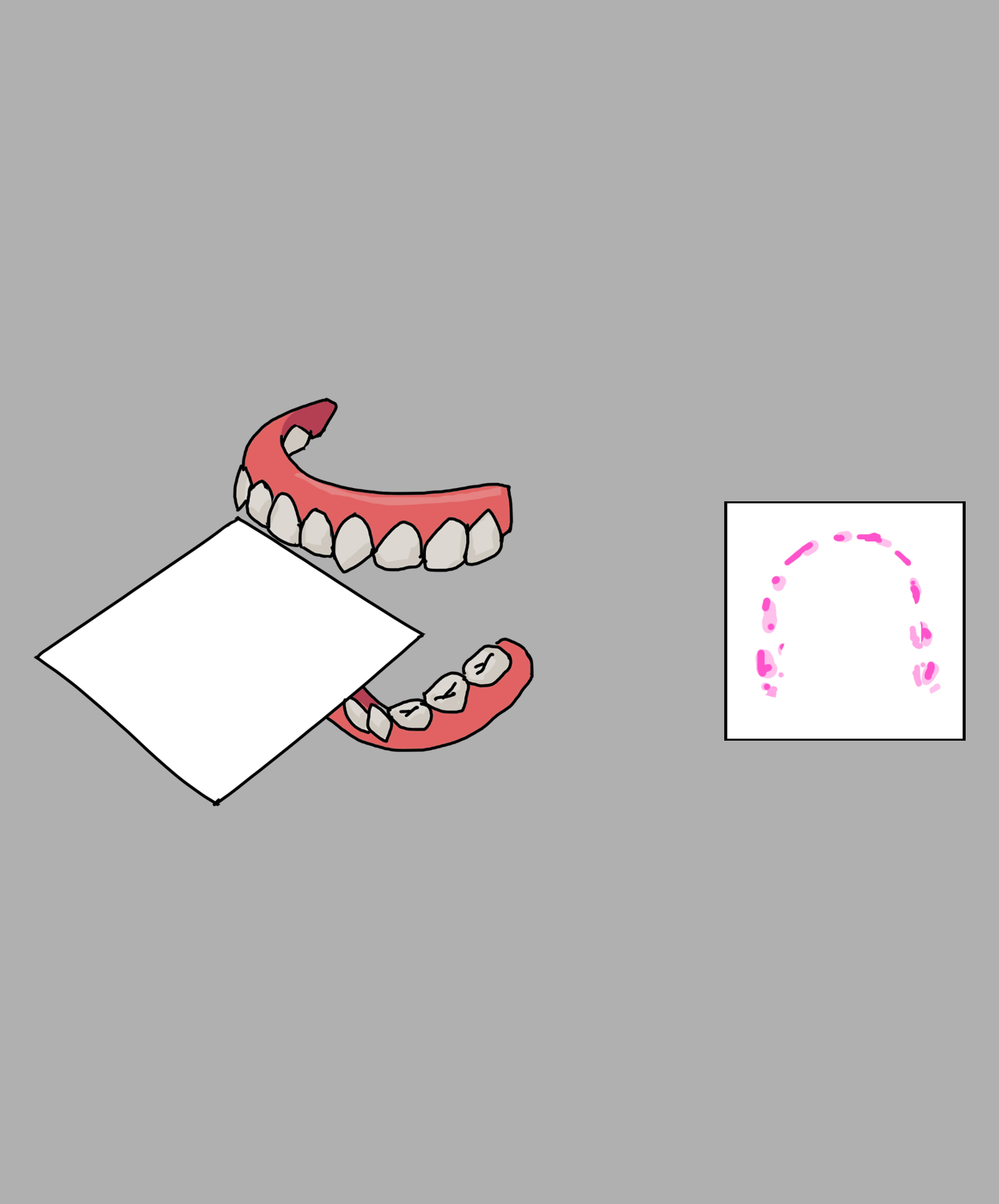

For many years, pressure analysis can only be performed through experience and guess. PF pressure film can judge the occlusal condition of patients' teeth through the depth of color. It is a very simple tool to provide dentists with occlusal images of patients and provide comparison between preoperative and postoperative, which is extremely economical and efficient.

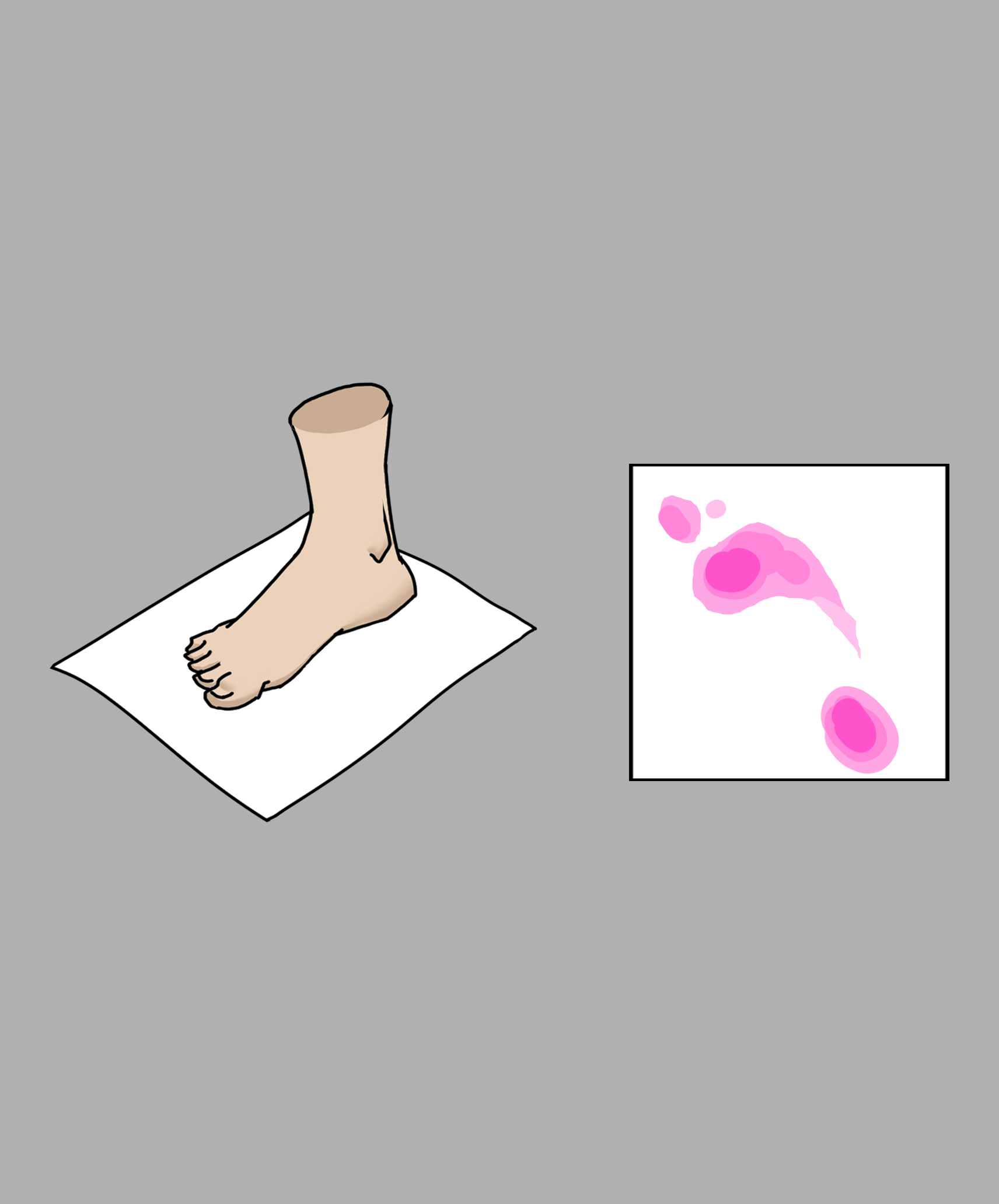

Traditional medical sole evaluation can only be conducted by doctors to check patients' foot, while PF pressure film can be used to easily obtain the pathological conditions of sole, such as arch foot, flatfoot, strephenopodia, strephexopodia, diabetic foot, etc.